News

资讯中心

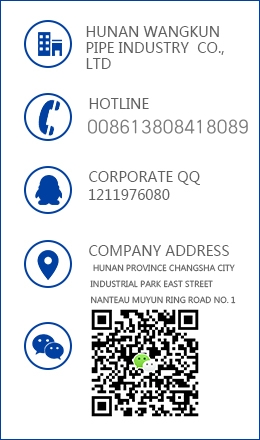

CONTACT US

联系我们

1.Groove fittings connection is simple

Stainless steel grooved fittings connection operation is very easy, no special specialized skills, ordinary workers can operate after simple training. This is because the product has been a large number of fine technical parts in a factory way into the finished product. The connection of pipe fittings takes only a few minutes, which simplifies the technical difficulties of on-site operation and saves working hours, thus stabilizing the quality of the project and improving the working efficiency. This is also the general direction of the development of installation technology.

The traditional welding and flange connection pipe connection, not only need to have the appropriate skills of the welders, and time-consuming, difficult for workers to operate, and there is welding fume pollution. Due to the differences in operating space and welding skills, it is difficult to achieve satisfactory results in welding quality and appearance, thus affecting the overall quality of the project. In addition, due to the groove fittings for finished products, the site requires little operating space, can really realize the installation against the wall by the corner, the operating difficulty is greatly reduced, thus saving the floor space and beautify the effect of pipe installation.

2, groove fittings without secondary processing

Stainless steel grooved fittings connection, only in the connection of the outer surface of the pipeline with rolling groove machine extrusion out of a groove, without destroying the inner wall structure of the pipeline, which is grooved fittings connection unique technical advantages. If the traditional welding operation is used, many of the inner wall of the pipeline has done the anti-corrosion layer will be damaged. Therefore, the specification provides for galvanized pipes, plastic-lined steel pipe, steel-plastic composite pipe, etc. shall not use welding and flange connection, otherwise it needs to be treated twice.

3, groove fittings connection construction safety

Using grooved fittings connection technology, the scene only needs cutting machine, rolling groove machine and button tightening bolts with moving hand, construction organization is convenient. The use of welding and flange connection, you need to be equipped with complex power cables, cutting machines, welding machines and oxygen and acetylene cylinders, etc., which brings complexity to the construction organization, and there is also a leakage of electricity and fire hazards. At the same time welding and gas cutting produced by the welding slag, inevitably fall into the pipeline, the use of pipeline valves and even easy to produce equipment clogging, but also contaminated water in the pipe.

In addition, welding and flange connection inevitably requires a long time of high-intensity overhead work, but also prone to production safety accidents.

4, groove fittings easy maintenance

Stainless steel grooved pipe fittings connection has a unique flexible characteristics, so that the pipeline has anti-vibration, anti-shrinkage and expansion of the function, compared with welding and flange connection, the stability of the pipeline system increases, more suitable for temperature changes, thus protecting the pipeline valves, but also reduces the pipeline stress on the destruction of structural components.

Due to the simple operation of groove fittings connection, the required operating space becomes smaller, which brings many convenient conditions for future maintenance. When the pipe needs to be repaired and replaced, just loosen the two pieces of clamps can be arbitrarily replaced, rotated, modified a section of piping. There is no need to destroy the surrounding walls, reducing maintenance time and maintenance costs.

Specializing in the production of various types of thin-walled stainless steel water pipes, single clamp fittings, double clamp fittings, stainless steel water pipes, clamp fittings, stainless steel manifold, grooved stainless steel fittings, socket welded fittings, butt-welded fittings, the company is equipped with production/sales/logistics/technical guidance/installation/after-sales service and other ancillary services department.

Translated with DeepL