News

资讯中心

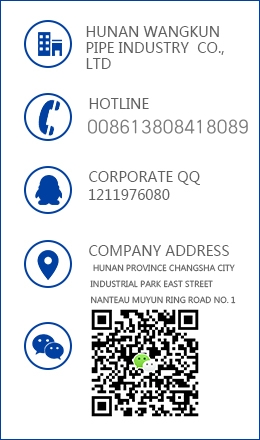

CONTACT US

联系我们

301 Stainless Steel exhibits significant work hardening during deformation and is used in a variety of applications where higher strength is required.

302 Stainless Steel is essentially a variant of 304 Stainless Steel with a higher carbon content, which can be cold rolled to obtain higher strength.

302 B is a stainless steel with high silicon content, which has high resistance to high-temperature oxidation.

303 and 303 Se are free-cutting stainless steels containing sulfur and selenium, respectively, and are used in applications that primarily require easy cutting and high surface finish.

Stainless steel 303 Se is also used in the production of machine parts that require hot heading, as this stainless steel has good hot workability under these conditions.

304 is a general-purpose stainless steel, it is widely used in the production of equipment and machine parts requiring good overall performance (corrosion resistance and molding).

304 L is a variant of the lower carbon content 304 stainless steel and is used where welding is required. The lower carbon content minimizes the precipitation of carbides in the heat-affected zone near the weld, which can cause intergranular corrosion (weld erosion) of stainless steels in certain environments.

304 N is a stainless steel containing nitrogen, which is added to increase the strength of the steel.

305 and 384 stainless steels contain high levels of nickel and have a low work hardening rate, making them suitable for a variety of applications where cold formability is important.

308 Stainless steel is used to make welding rods.

309, 310, 314 and 330 stainless steels have high nickel and chromium content to improve the oxidation resistance and creep strength of the steel at high temperature. 309 S and 310 S are variants of 309 and 310 stainless steels, differing only in their lower carbon content in order to minimize carbide precipitation near the weld. 330 stainless steels have a particularly high resistance to carburization and to thermal shock.

Types 316 and 317 stainless steel contain aluminum, and thus have much better resistance to pitting corrosion than 304 stainless steel in marine and chemical industry environments. Among them, the variants of type 316 stainless steel include low-carbon stainless steel 316 L, high-strength stainless steel 316 N containing nitrogen, as well as high sulfur content of free-cutting stainless steel 316 F.

321, 347 and 348 are titanium, niobium plus tantalum, niobium stabilized stainless steel, suitable for high temperature use of welded components. 348 is a kind of stainless steel for the nuclear power industry, the tantalum and cobalt have a certain amount of limitations.

24-hour customer service hotline: If you are interested in stainless steel water pipe or have questions, please click to contact our web page online customer service, or call: 13974980698 Hunan Wangkun Pipeline Industry--your whole process of attentive procurement consultant.