News

资讯中心

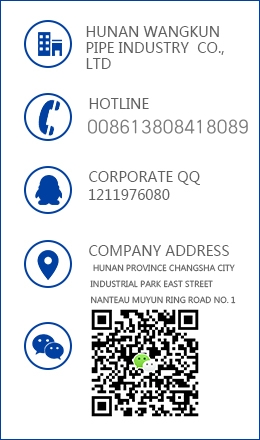

CONTACT US

联系我们

At present, the domestic industrial welded pipe enterprises are mainly concentrated in Jiangsu and Zhejiang, South China, industrial welded pipe enterprises are few, the future development space is very large;

Wangkun Pipe is the first stainless steel water pipe manufacturer in Hunan, specializing in thin-walled stainless steel pipes and fittings, double-clamping stainless steel pipe, stainless steel pipe for natural gas, stainless steel gas pipe, double-clamping thin-walled stainless steel water pipe for home furnishing, stainless steel drainpipe, stainless steel rainpipe, stainless steel siphon drainpipe, food-grade stainless steel pipes and fittings research and development.

Stainless steel water pipe prospects are even broader, whether from the economy, environmental protection, health perspective, or the strategic level of sustainable development, stainless steel water pipe will be popularized in the future, the current domestic stainless steel water pipe enterprises began to spring up all over the country, the future will also be opened up to the global market, to benefit the health of mankind plate, with the rapid development of China's economy, the popularity of food-grade and hygienic grade With the rapid development of China's economy, the popularization of food-grade and sanitary stainless steel pipe, has been imminent, but now the domestic market can not meet the growing demand. Specifically, you can see the following analysis!

Stainless steel industrial pipe is divided into.

304L stainless steel industrial tube, 304 stainless steel industrial tube, 310 stainless steel industrial tube, 303 stainless steel industrial tube, 302 stainless steel industrial tube, 301 stainless steel industrial tube, 202 stainless steel industrial tube, 201 stainless steel industrial tube, 410 stainless steel industrial tube, 420 stainless steel industrial tube, 430 stainless steel industrial tube and so on.

304L Stainless Steel Industrial Pipe:As a low carbon 304 steel, in general, the corrosion resistance is similar to 304, but after welding or stress relieving, its excellent resistance to grain boundary corrosion, in the absence of heat treatment, but also can maintain good corrosion resistance.

304 stainless steel industrial tube: good corrosion resistance, heat resistance, low temperature strength and mechanical properties, stamping, bending and other hot workability, no heat treatment hardening phenomenon. Uses: tableware, cabinets, boilers, auto parts, medical appliances, building materials, food industry (use temperature -196°C-700°C)

310 stainless steel industrial tube is mainly characterized by: high temperature resistance, generally used in boilers, automobile exhaust pipe. Other properties in general.

303 stainless steel industrial tube: by adding a small amount of sulfur, phosphorus to make it easier to cut and process than 304, other properties and similar to 304.

302 stainless steel industrial tube: 302 stainless steel bar is widely used in automobile parts, aviation, aerospace hardware tools, chemical industry. Specific as follows:Crafts, bearings, slip flowers, medical instruments, electrical appliances and so on. Characteristics:302 stainless steel ball belongs to austenitic steel, and 304 is closer, but the hardness of 302 is a little higher, HRC ≤ 28, with good rust and corrosion resistance

301 stainless steel industrial tube: good ductility, used for molding products. It can also be hardened quickly by mechanical processing. Weldability is good. Wear resistance and fatigue strength is better than 304 stainless steel.

202 stainless steel industrial tube: belongs to the chromium - nickel - manganese austenitic stainless steel, performance is better than 201 stainless steel

201 stainless steel industrial pipe: belongs to the chromium-nickel-manganese austenitic stainless steel, low magnetic properties

410 stainless steel industrial tube: belongs to the martensitic (high strength chromium steel), good wear resistance, corrosion resistance is poor.

420 Stainless Steel Industrial Tubes: A "cutlery grade" martensitic steel, similar to Brinell high-chromium steel, the earliest stainless steel. Also used for surgical knives, can be made very bright.

430 Stainless Steel Industrial Tubes: Ferritic stainless steel for decorative purposes, e.g. for automotive accessories. Good molding properties, but temperature resistance and corrosion resistance to be poor.

Stainless steel water pipe, is the best pipe for direct potable water delivery. It has a very low leakage rate and can save valuable water resources characteristics. The water pipe leakage rate in the 1980 was around 17%, and the leakage rate dropped to 7% after switching to stainless steel water pipes. The water supply system was damaged in the earthquake, but the stainless steel plumbing system is intact. In addition, compared with copper water pipes, stainless steel water pipes have good water permeability and do not corrode at high flow rates.

Advantages of stainless steel water pipes

01 | Health

Stainless steel material is a healthy material that can be implanted in the human body, so the choice of stainless steel piping is the most favorable to the health of the water supply pipe. Immersion water test, the indicators are in line with the requirements of the relevant national drinking water standards. Stainless steel pipe wall is smooth, long-term use will not accumulate scale, not easy to be bacterial staining, no need to worry about the impact of water quality, and more to eliminate the secondary pollution of water.

02 | Selection of materials

All raw materials used in the grade 304, 304L, 316, 316L, are in line with the requirements of JIS4305. The above grades are characterized by stable performance, high strength and low coefficient of thermal expansion.

03 | Durable

Stainless steel surface thin and dense chromium-rich oxide film, making stainless steel water pipe in all water qualities, including soft water, have good corrosion resistance, even if the buried use has excellent corrosion resistance; field corrosion test data show that the service life of the stainless steel water pipe up to 100 years, the life cycle of virtually no maintenance, to avoid the cost of replacement of pipeline and trouble, the comprehensive use of low cost.

04 | High temperature and pressure resistance

Stainless steel can work safely for a long time under the temperature of -270 ℃ -400 ℃, whether high or low temperature, will not precipitate harmful substances, the material performance is quite stable; stainless steel water pipe tensile strength greater than 530 N/mm, and has good ductility and toughness. The high strength of stainless steel water pipe greatly reduces the possibility of leakage by external forces, significantly reducing the water leakage rate, so that water resources are effectively protected and utilized.

05 | Energy saving and environmental protection

Stainless steel pipes have smooth inner walls and very low water resistance, which reduces pressure loss and lowers transportation costs. Due to the low coefficient of thermal expansion of stainless steel, heat loss is effectively reduced in hot water piping. Stainless steel material is 100% renewable material, will not cause public harm to the environment.

06 | Wide range of use

Stainless steel pipe can be widely used in cold water, hot water, drinking water, air, gas, medical gas, petroleum, chemical, water treatment and other piping systems.

07 | Economical and practical

Since the invention of stainless steel in the 20th century, stainless steel is now a common material. At present, in the performance-price ratio of various materials of water pipes, the best is stainless steel water pipes. This is related to the stainless steel material corrosion resistance, high strength, strong impact resistance and other superior performance. Its service life can be said to be the same life with the building. Once invested, lifelong benefit, can be said to be "once and for all".

Folding stainless steel water pipe connection

1, extruded connection --------- radial contraction force (hydraulic clamp) will be used to pipe fittings clamped on the pipe, and through the O-ring water stop, to achieve the effect of connection. Connection strength is low (interface connection strength is less than 1/3 of the strength of the tube body), the pipe is not removable; tube port burrs, flying edge removal is not clean will damage the rubber ring, and become a hidden danger of future water leakage.

2, expand the ring type connection --------- using radial contraction of external forces (hydraulic clamp) will be fastened to the pipe fittings, and through the wide band of rubber sealing ring of the water, to achieve the effect of the connection, removable, tube installation to increase the tube end of the rolling convex ring process; casting fittings at a higher cost, the strength of the interface than the clamping type is good.

3, welded connection --------- using hot melt process, the two connectors fusion, to achieve the effect of connection. Connection strength is high, the weld gas protection of the field welding port is difficult to meet the standard, resulting in weld rust easily, directly reducing the service life of the pipeline; the installation quality of the welding workers technology is highly dependent on the quality is difficult to stabilize

4, a new type of connection ---------- typical insertion of self-locking card spring type connection, is currently one of the easiest construction methods. Operation is simple and convenient, construction workers only need to familiarize themselves with its operational requirements, a little practice can be mastered. Connection, the tube cut end should be perpendicular to the axis of the tube, the burr inside and outside the cut should be cleaned up, and use a marker pen on the outside of the front end of the copper tube to mark the depth of the need to be inserted, and then force the copper tube inserted into the fittings in the end to the end of the tube stop can be.

(1)Simple installation, no need to process the thread or rely on the wall thickness of the tube to connect, and avoid the difficult to

control of the human factor.

(2) With labor-saving, time-saving, material-saving, tool-saving, site-saving, environmental protection, sustainable use and many other advantages

(3) Low installation risk, suitable for a variety of installation environments, reusable, environmentally friendly and energy-saving.

(4)Non-leakage, shockproof, anti-heat expansion and contraction, safe to use, durable and reliable.

Folding

Classification of stainless steel water pipe

1, according to the production method classification.

(1) seamless pipe - cold drawn pipe, extruded pipe, cold rolled pipe.

(2) Welded pipe.

(a) Classified by process - gas shielded welded pipe, electric arc welded pipe, resistance welded pipe (high frequency, low frequency).

(b) According to the welding seam - straight seam welded pipe, spiral welded pipe.

(2) Classified by wall thickness - thin-walled steel pipe, thick-walled steel pipe

3、Categorized by material.

(1) 304 stainless steel water pipe;.

(2) 304L stainless steel water pipe.

(3) 316 stainless steel water pipe; (4) 316L stainless steel water pipe; (5) 316L stainless steel water pipe

(4) 316L stainless steel water pipe.

Water pipe can be classified from the material can be divided into three categories: metal pipe, composite pipe, plastic pipe.

Metal pipe:

1, galvanized pipe: the use of this water pipe is easy to produce rust scale inside the pipe, out of the water is not only contaminated sanitary ware, breeding bacteria, and the high content of metal substances in the water, endangering human health, is now banned by the state when the drinking water pipe.

2, copper pipe: more traditional good water pipe, corrosion resistance, if connected with ordinary fittings over time there will be leakage problems, if you take the welding process will be much safer.

3, stainless steel pipe: stainless steel material has excellent corrosion resistance, hygiene, no rust, no scaling, no seepage release of foreign matter, good self-cleaning, long service life, environmental protection, can be 100% recycled, the water quality will not cause secondary pollution, is one of the most excellent pipeline transportation materials, the future to replace the other material pipeline the chances of a very large.

Composite pipe:

1, aluminum-plastic pipe: once more popular, easy to construct, have better thermal insulation performance, internal and external walls are not easy to corrode, but should not be buried underground, card joints are easy to leak.

2, copper-plastic pipe: and aluminum-plastic pipe is almost the same, usually about 3 meters long, but more joints, easy to junction copper green.

3, steel-plastic pipe: steel-plastic pipe is the traditional galvanized pipe upgraded products, health and non-toxic, non-accumulation of dirt, corrosion-resistant, smooth wall, long service life.

Plastic pipe:

1, UPVC pipe: the interface is generally glued, frost and heat resistance are not good, so the hot and cold water pipes are rarely used, PVC pipe for electrical wiring and sewage pipes.

2, PPR pipe: the more perfect water pipe, non-toxic, corrosion-resistant, heat fusion seamless connection, can be used for hot and cold water pipes, can also be buried, but the installation is difficult, easy to leak.

3, PE-RT pipe: the heat resistance of this water pipe is very good, can be used for ISO10508 in the provisions of all the use of hot water pipe level, often used for hot water pipe.

4, PPH pipe: this pipe is often used to do sewage water pipe, waste water pipe, rain water pipe, but the installation method as far as possible using welding.

5, PEX pipe: this pipe has good pressure resistance, wide range of temperature resistance, acid and alkali corrosion resistance, can be used to transport chemicals, not scaling, easy to install, long service life, the biggest drawback is that it can not be welded, so it is not suitable for application in the ventilation and heating.